Hardfacing Patterns

When applying Tungsten we recommend applying Tungsten to areas of high impact and abrasion. The customer may suggest where they think it should be applied based on their personal experience with the part.

As with welding any high carbon/high strength steel care attention must be applied with preheating the base material to avoid embrittlement in the welding zone which could lead to failure of your part or unsuccessful application of the tungsten product.

If working with a new part that doesn’t show signs of wear we recommend the following:

Selection of the proper hardfacing alloy and preparation of the workpiece are not enough to maximize the service life of a part.

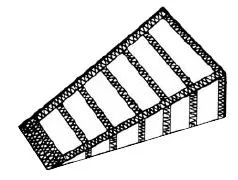

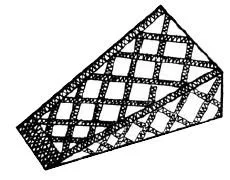

The pattern used to make the overlay must also be considered, as it too, will have a bearing on how long the part will last. There are times when putting less hardfacing on a surface is better than covering the entire surface. There are a number of ways that stringer bead patterns are used depending on the service conditions of the component.

Stringer beads parallel to path of rocky material

Stringer beads at right angles to path of fine sandy material

Stringer beads in checker or waffle pattern for mixed conditions or wear fine material might easily pack

Dot Pattern for less critical areas

For parts that have a sharp edge from factory or had a tight fit tolerance within a machine we recommend letting the part wear down before building back up with tungsten.